Here is a breakdown of the new EN 17451 standard for the design, assembly, installation and commissioning of pumping units, based on EN 12845

The fire pump assembly manufacturing, installation and maintenance industry in Europe, including countries such as the United Kingdom, is in a time of regulatory transition.

Limitations of EN 12845

To date, EN 12845 has been the main tool for describing the conditions and requirements for fire sprinkler systems, including diesel or electric driven pumps.

In addition to pump specifications, EN 12845 also covers risk classification, hydraulic design criteria, water supply, sprinkler distribution and location, piping sizing and configuration, valves, etc.

These characteristics are applicable to the design, construction, installation and maintenance of a number of elements that may distract the attention of professionals or companies whose main focus is the supply of pressurized water through pumps.

However, the need for greater clarity and specificity has led to the creation of the new EN 17451 standard, which focuses exclusively on fire pump assemblies and will soon come into force.

Objective of the new EN 17451 standard: to create a document of high technical level, similar to NFPA 20

The aim of the EN 17451 standard is to clarify, specify and correct concepts and, above all, to provide a more specific and technical document that will be widely used in Europe, thus creating a tool comparable to the popular NFPA 20 standard in the United States.

This standard focuses exclusively on stationary fire pump assemblies in sprinkler systems and provides clear and detailed guidelines for their design, assembly, installation and commissioning.

Thus, the new EN 17451 standard, which has already been drafted and revised by the expert committee and is already close to publication, focuses exclusively on aspects related to fire pump assemblies and their enclosed environment. Some key aspects:

Pumping set design and assembly

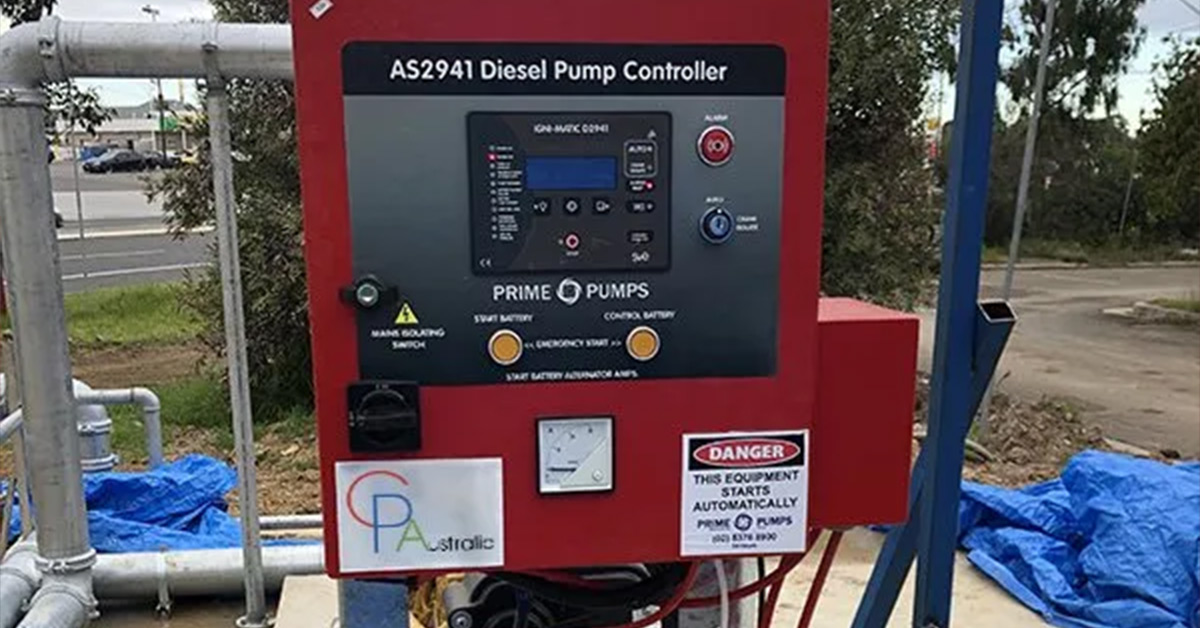

EN 17451 details the requirements for the design and assembly of pump assemblies in accordance with EN 12845. This includes all parts and components necessary to ensure efficient and safe operation.

Identification of essential components

The essential components of pumping units are specified, which facilitates their identification and ensures that all critical elements are present and correctly installed.

Component performance characteristics

The standard also describes the performance characteristics of components used in pumping units to ensure that each part performs optimally and contributes to the efficiency of the system as a whole.

Performance test requirements for diesel and electric pump units

To ensure the reliability and efficiency of pumping units, EN 17451 sets out clear requirements for performance testing of both diesel and electric pumps. These tests are essential to verify that the equipment meets the required standards prior to commissioning.

On-site testing, commissioning and delivery

The standard provides guidelines for on-site testing, commissioning and delivery of pumping units. This process ensures that the systems are fully operational and ready for use in emergency situations.

Documentation

Finally, EN 17451 emphasizes the importance of adequate documentation. This documentation should include all relevant details of the design, installation, testing and commissioning of pumping units, providing a complete and accessible record for future reference.

The new EN 17451 represents a significant step forward for the fire pump industry in Europe, providing clear and specific guidance for the design, assembly, installation and maintenance of these critical systems.

Do you have any questions or need more information on implementing EN 17451? Contact our experts to ensure your installations meet the highest standards of safety and efficiency.